Wooden architecture

“Urban Timber Building” Activities

In its efforts to help realize a low-carbon society and contribute to regional revitalization through urban development, Takenaka is innovating technologies to promote the use of timber in building.

“Urban Timber Buildings”—that is, urban buildings built using timber instead of steel and concrete-- are expected to become “keystones” supporting urban development in the future.

We are promoting “Urban Timber Buildings using new, advanced wood technologies such as “Moen-Wood” fire-resistant laminated lumber, wooden seismic reinforcement “T-FoRest”, and CLT (Cross Laminated Timber) technology. Our aim is to create a link between productive forestation and the city.

Wooden architecture: Growing Momentum

The government is taking various measures to promote the use of timber in the construction field. The Building Standards Act was revised in 2000, so that any building could be built with wood, if it fulfills a certain level of performance. With this revision of law as a start, the subsequent “Act on Promotion of the Utilization of Wood in Public Buildings” made the use of timber mandatory for low-rise institutional buildings, helping drive momentum for the growing use of timber in constructing buildings.

The use of wood for architecture is gaining a lot of public attention. It is not only contributing to the regeneration of Japanese forestry; but also reviving cultural memories, that recall the intimate “warmth and comfort” of wood.

Two Aspects of Takenaka’s Wooden architecture Activities

In the 1990’s, when we were developing and building large domes such as the Tokyo Dome and the Nagoya Dome, we used the latest timber technology then available.

The use of large glulam technology for the Hakuryu Dome and the use of domestically produced timber for the Odate Jukai Dome pioneered today’s use of timber in architecture.

The keel arch made from large glulam used for the Hakuryu Dome (Hiroshima prefecture; completed: 1992).

This arch was made using the (Big) Finger Joint construction method, which was becoming popular in Europe but had not been used in Japan before.

A timber beam with a span of 50m and bridges and supports the roof of the gymnasium.

The Odate Jukai Dome (Akita Prefecture; completed: 1997, known as Nipro Hachiko Dome) uses 4000㎡ of locally produced cedar.

We overcame the weaknesses of domestic cedar, which is not as strong as its foreign counterparts to construct the world’s largest wooden dome for baseball.

We used the latest available technology to meet the needs of the stakeholders to “promote wooden architecture” mindful of regulations governing the use of such materials.

In 2000, because of the revision of the Building Standards Act mentioned previously, the regulations relating to wooden architecture changed and we thought it would be possible to meet even more of the needs mentioned above with new approaches.

The 2 approaches are:

- Creating advanced “timber Innovation” through the development of wooden architecture technologies.

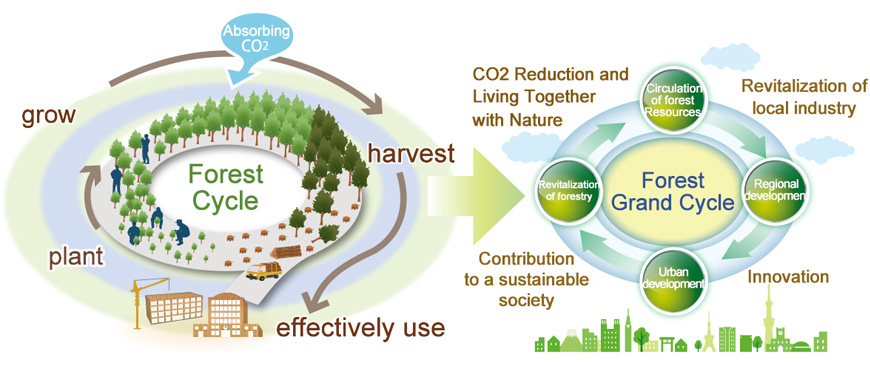

- The creation of a “Forest Grand Cycle” leading to the revival of forestry and forest regeneration, revitalizing regional development while at the same time contributing to urban development.

The Creation of “Timber Innovation”

Increased use of timber in buildings represents various challenges including fire and seismic safety, durability issues, and the like. Takenaka is “creating timber innovation” through a combination of technological development, design, and construction capabilities. The results are architectural accomplishments that contribute to society.

Our innovation implements activities to solve social issues, and at the same time, redraws the future of cities, taking advantage of the unique qualities of timber such as warmth and comfort.

New Takenaka-developed technologies such as “Moen-wood” are representative of “timber innovation” and demonstrate how we can solve problems using timber.

Glued laminated lumber with fire-resistant performance “Moen-wood”

Moen-wood adopted in a car showroom in the city

Creating A “Forest Grand Cycle”

“Timber innovation” and utilization of forest resources can activate the economy and circulation of wealth and resources between urban and rural areas. Forests can revitalize regional economies and urban development promoting sustainability, making prefectures with forest resources central to the economy. Increased demand for wood in construction will revive Japan’s forest industry.

This resource and economic cycle linking the forest industry, regional revitalization, community building and construction is Takenaka’s Forest Grand Cycle concept which we are working to implement, with stakeholders in each field, including forestry organizations and local governments.

The “Forest Grand Cycle” links utilization of forest resources and the economic development of society in a continuous cycle, beyond the simple plant-grow-harvest-use model.

Takenaka is actively using domestic timber bearing the Domestic Timber Mark for its “Moen-wood”.

The Comfort of Wood: Appealing to the Five Senses

Timber’s moisture and insulative performance can improve the energy saving performance of a building while offering human comfort in terms of regulation of cold and heat.

Most wood used in construction is about 15% water by weight under typical temperatures and humidities in Japan. As humidity increases, the wood absorbs moisture. As it decreases, it releases it. Therefore, using wood for building interiors helps control humidity conditions.

The low heat transfer rate or thermal conductivity of wood—one tenth that of concrete and one-five hundredth that of steel—makes it a high performance insulation material. Using wood you get buildings that are cool in summer and warm in winter.

Research into the Comfort of Wood

The advantages of wood in terms of human comfort, including its tactile appearance, smell, and insulative and moisturizing characteristics have been scientifically verified. As a result, we can expect more and more medical and nursing facilities to use wood.

Takenaka Corporation will continue to contribute to the realization of wooden architecture technologies and their promotion and use.